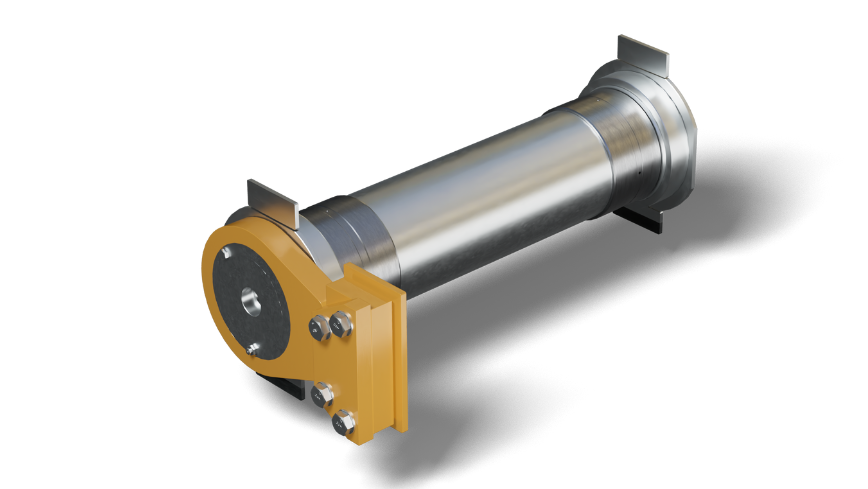

Improvement Factors of the Geographe Enhanced Performance™ (EP) Solid Kit Pin

The Challenge Faced with Bucket Bushes and Oil-Filled Cartridge Pins

We received reports from several mining customers highlighting premature wear issues observed in the CAT 992G Bucket Bush and oil-filled cartridge pins. The OEM design of these crucial parts has introduced several challenges affecting both operational efficiency and maintenance costs.

One of the primary issues associated with oil-filled cartridge pins is their propensity to leak. While the design aims to provide lubrication and reduce friction, it often results in seal failures and subsequent oil leakage, not only compromising the pin’s effectiveness but also posing the risk of contaminating surrounding components and the working environment. The leaking oil can be detrimental to the operation of the excavators and can cause catastrophic failures.

The poor design, coupled with the mine site’s harsh conditions, accelerates wear and tear of the cartridge pin, leading to unscheduled, extended downtime and costly repairs.

How We Solved Premature Wear Issues With Our EP Solid Pin Kit

To solve the premature wear in both the bucket bush and cartridge pin, we engineered the Geographe Enhanced Performance™ (EP) Solid Pin Kit (SPK) with redesigned bush features and mating parts. The EP SPK has a greased design to reduce the probability of leakage and catastrophic failure while offering a cost-effective solution to premature failures experienced with the original oil-filled pin, by reducing maintenance time during changeouts.

The Geographe Enhanced Performance (EP™) Solid Pin Kit has reduced the total cost of ownership for our national and international mining customers, increasing fleet uptime and supporting the bottom line.

Improvement Factors of the Geographe Enhanced Performance™ (EP) Solid Kit Pin

-

Faster, more efficient bucket and parts changeouts.

-

Upgraded materials and hardness, increasing operational life.

-

Decreased machine downtime during maintenance events.

-

Multiple components under one part number and one price, means all parts are despatched in one crate, improving convenience.

-

Eased dismantling due to seals in the static bushes, which stop the ingress of corrosive elements.

Be abreast of Enhanced Performance Solutions for Mining Parts

How can we help?

Submit your details below and our team will contact you.