A common challenge within CAT 7-Series Haul Trucks is the seizing of its Standard Rear Strut/Rear Suspension & Sway Bar Pins, making extraction risky and very time-consuming due to the use of hot works to lance out the pins.

The use of hot works as thermal lancing is part of routine maintenance practices of mining heavy machinery. While this method is effective in removing worn components, it poses significant safety risks and can incur substantial costs from extended fleet downtime to lance out the seized pins.

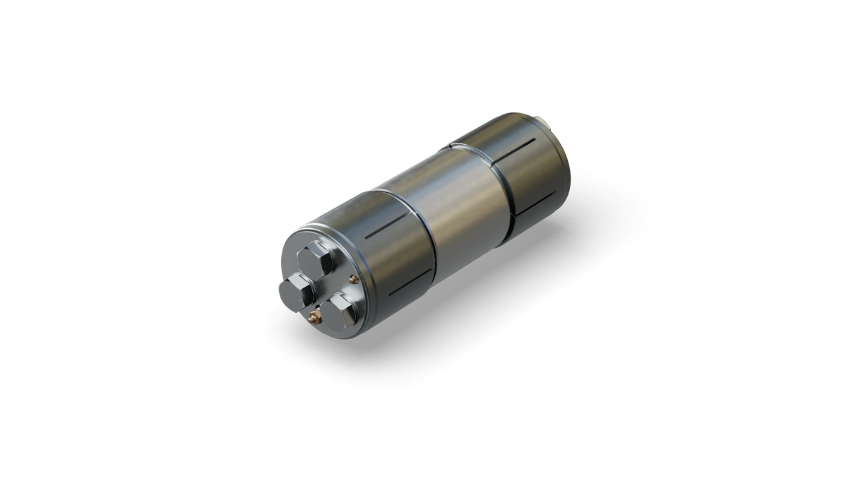

Introducing the Geographe EP Colleted Pin Assembly (CPA)

Responding to this concern, we engineered the Geographe Enhanced Performance™ (EP) Colleted Pin Assembly (CPA) – a solution specifically designed to be a safer and cost-effective alternative for pin changeouts on Caterpillar 7-Series Haul Trucks, without resorting to thermal lancing practices.

By employing a tapered collet system, the CPA creates a self-wedging effect between the pin and frame bores, effectively eradicating pin seizures. This kit contains a lightweight design aimed at minimising handling risks and deviations from safe work practices while facilitating installation and removal. By making maintenance more efficient, the CPA reduces machine downtime, ultimately contributing to enhanced productivity.

Proven Benefits of the Geographe EP CPA

- Reduces the need for hot works, decreasing deviation from safe working procedures.

- Increases fleet uptime with efficient extraction.

- With the Collet Pin fixed in the housing, it protects the bore from wear and eliminates the need for line boring on change out.

With no major modifications required to critical parts of the machine for fitment of the Geographe EP CPA, it allows for complete interchangeability with Caterpillar & Geographe components.

Read more in Geographe's feature in MINE Australia's March 2024 edition here

Be abreast of Enhanced Performance Solutions for Mining Parts

How can we help?

Submit your details below and our team will contact you.